Common Types of Additives and Modifications

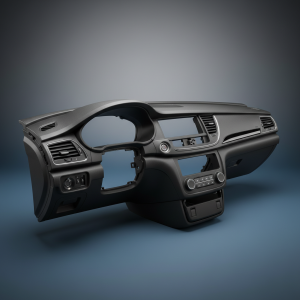

Engineering Plastics | General Purpose Plastics | EMI Shielding | ESD - Electrostatic Dissipative | Blow Molding Grade

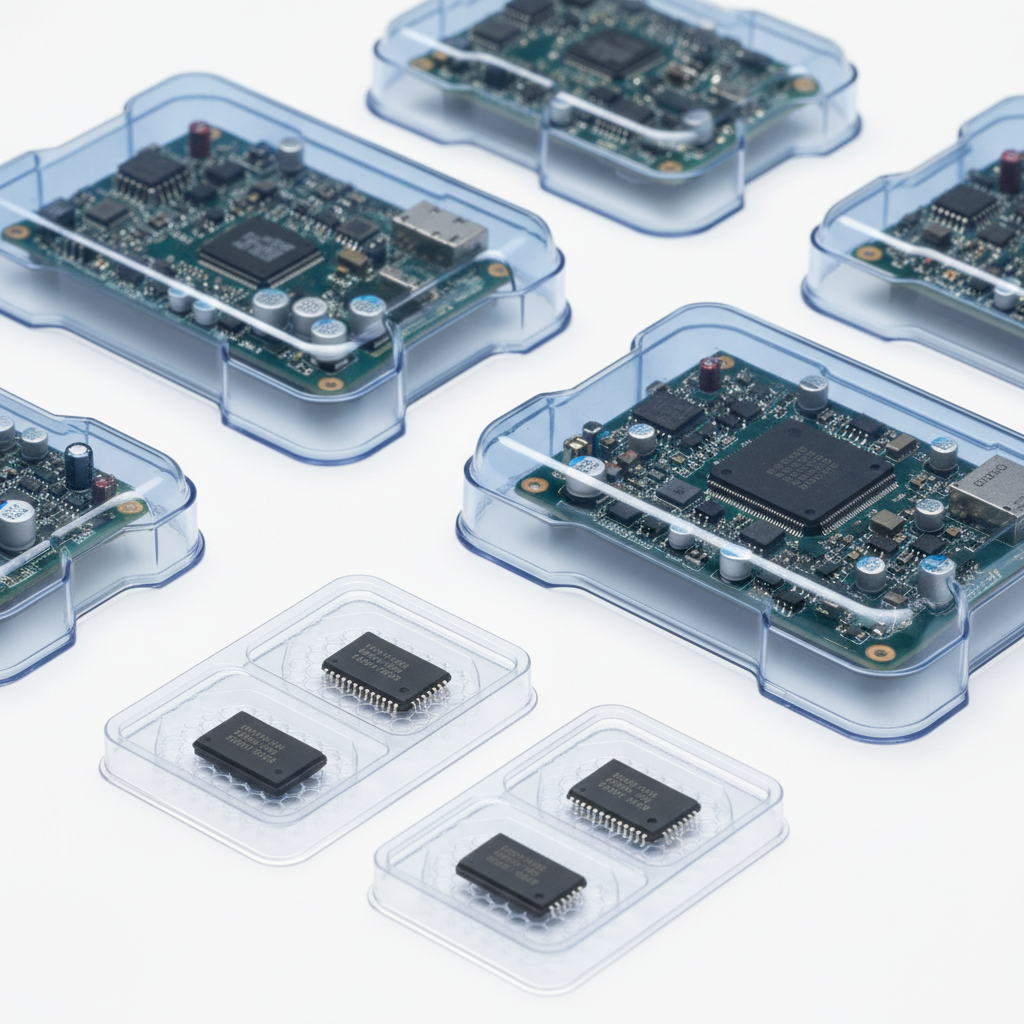

Carbon-Based Fillers: This is the most widely used category[9] . Carbon Black: Valued for its high conductivity an...

- Rosh

- Good dimensional stability

- Good chemical resistance

- Good creep resistance